Project Overview

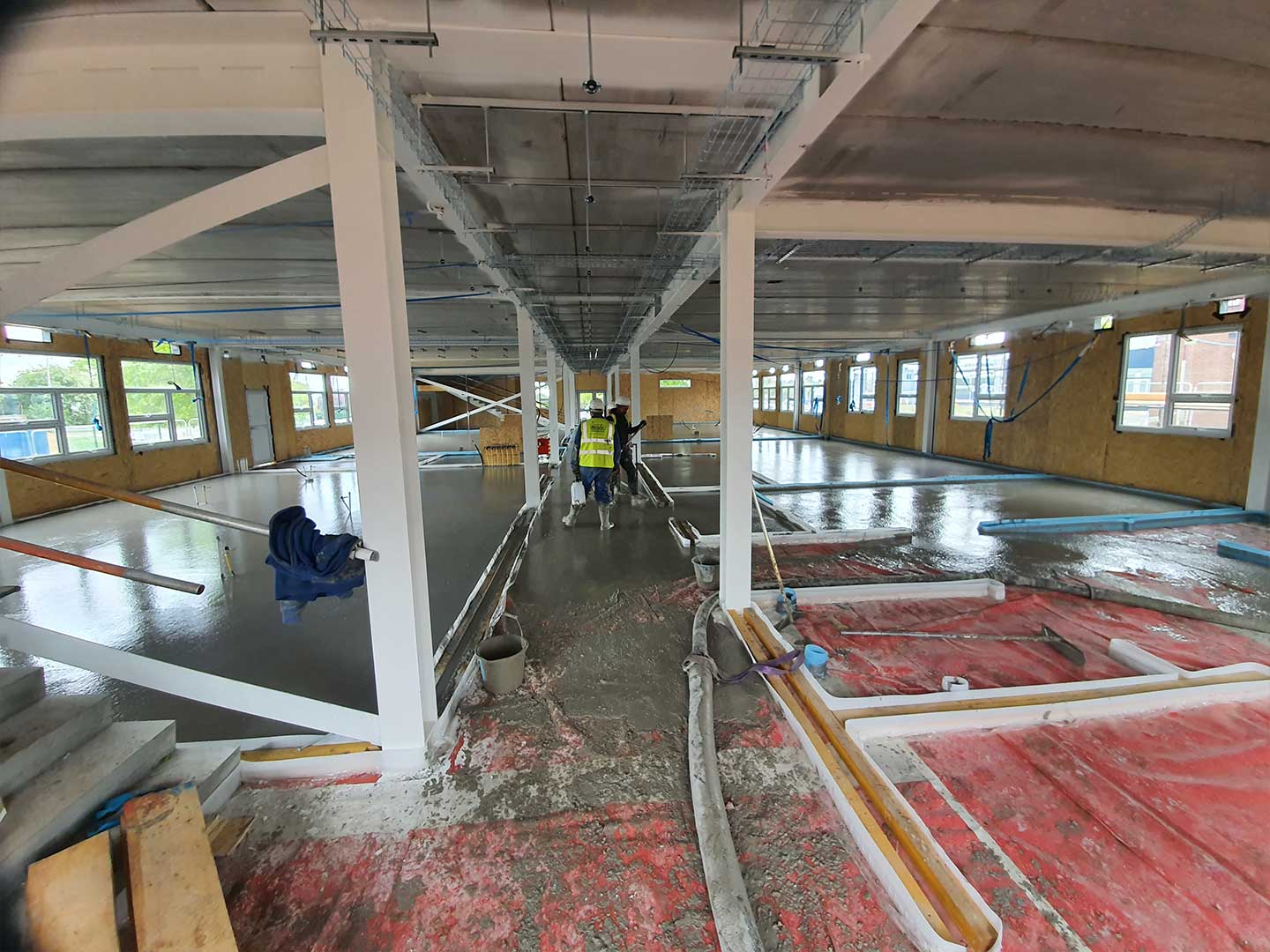

Trent Construction Services carried out the flowing screed installation at the new Surgical Elective Centre within John Radcliffe Hospital, Oxford.

The project, led by MTX Structures, forms part of a rapid-build healthcare development for Oxford University Hospitals NHS Foundation Trust, due to open in 2026. The new facility is designed to increase surgical capacity, reduce waiting lists, and separate elective procedures from emergency care.

Scope & Requirements

Trent installed over 2,000m² (172m³) of liquid screed, poured over three days and bonded onto a ground floor in-situ concrete slab.

The project followed a modular construction concept, with off-site assembled units installed onto a concrete base. The fast-track build and short availability window – only one week for screed installation – required a high-performance liquid screed capable of rapid strength gain and excellent hardened properties.

Because a bonded screed was specified, careful attention was given to substrate preparation, bonding agent selection, and joint layout to ensure long-term durability and adhesion.

Solution Provided

Trent installed Longfloor Liquid Cement Screed, supplied by Cemex from their Witney depot, selected for its proven performance on bonded applications and rapid strength development.

To manage the complex logistics of pumping both at height and over long distance, Trent utilised their own dedicated pumping solution with a 50mm hose, providing greater control and accuracy during placement.

As an existing approved contractor for MTX Structures, Trent was able to deliver a complete service package, providing the plant, pumping equipment, and skilled installation team. Their established relationships within the supply chain ensured efficient sourcing and reliable delivery of all materials within the project’s demanding timeframe.

Results & Benefits

The flowing screed installation was completed over three successive days, with pour volumes of 63m³, 56m³, and 53m³. The first day’s pour represented a record volume for both Cemex and Longfloor.

The floors were handed over to the client achieving a level tolerance better than SR2, with no cracking and a high-quality surface finish.

By completing works within the one-week window, Trent enabled the client to continue their fast-track programme, allowing partition installation to begin the following week.

Project Highlights

| Client: | Oxford University Hospitals NHS Foundation Trust |

| Principal Contractor: | MTX Structures |

| Screed Supplier: | Cemex (Longfloor Liquid Cement Screed) |

| Location: | John Radcliffe Hospital, Oxford |

| Sector: | Healthcare |

| Scope: | Bonded liquid screed installation |

| Area Installed: | 2,000m² / 172m³ |

| Programme Duration: | 3 days |

| Completion: | 2025 |

| Finish Tolerance: | Better than SR2 |

| Record Achieved: | Largest single-day pour for Cemex and Longfloor |

“Trent Construction Services delivered their works efficiently and to a high standard, helping the project stay on track.”

– Project Manager, Oxford Surgical Elective Centre

“I would just like to thank you for using our Longfloor IntegraCure material on the hospital project in Oxford recently, which is a great success for all involved.

The quality of floors that were delivered for your client, are testament your high standards of workmanship and a comprehensive understanding of what is required when using our materials. We look forward to working alongside you again on future projects.”– Lee Shaw, National Longfloor Manager