Bringing the Cream to the Top: Professional Power Floated Concrete Services

Power floated concrete floors are mechanically finished using rotating blade machines to create smooth, dense surfaces suitable for heavy industrial use without additional toppings.

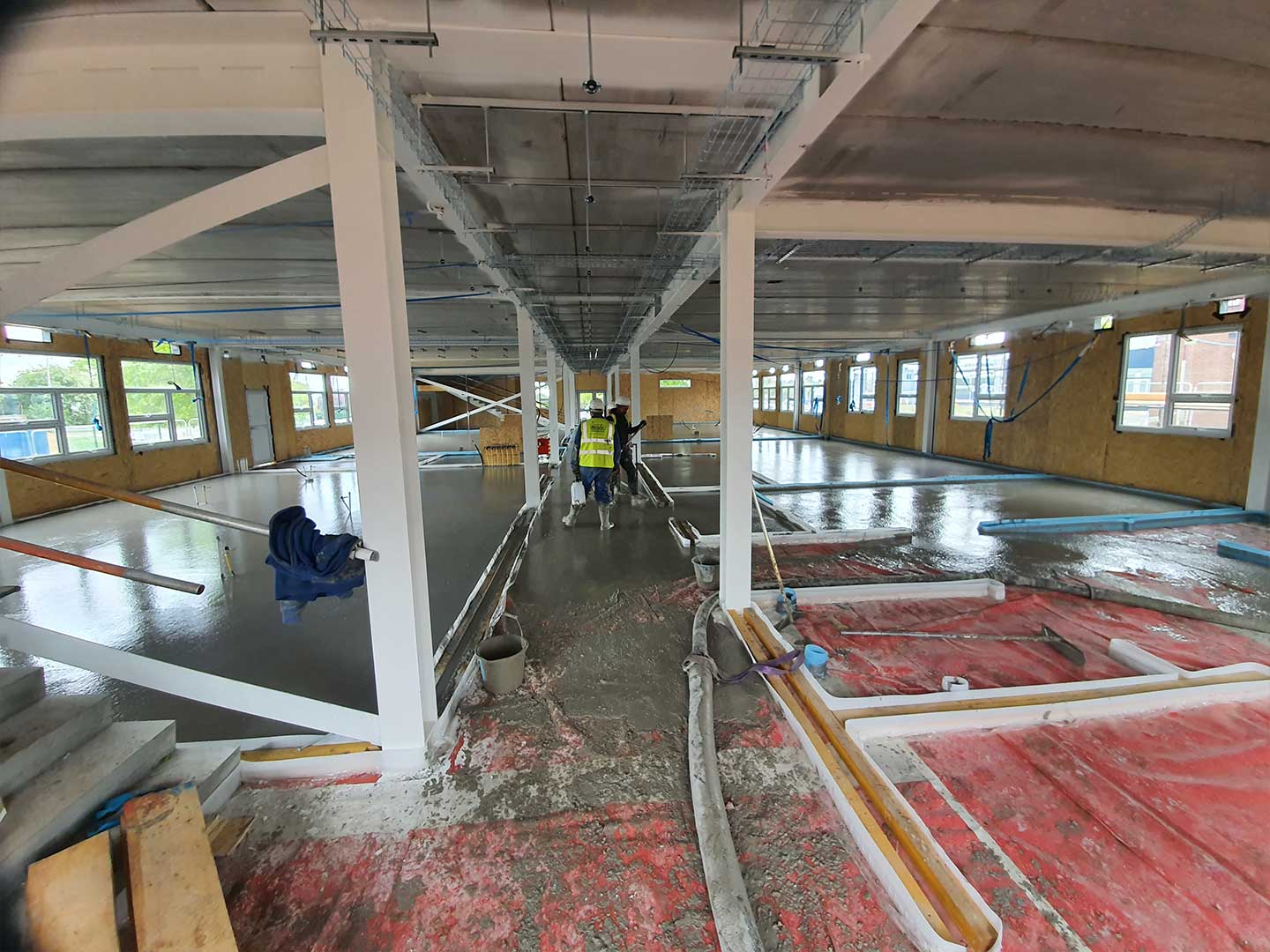

The process brings that cement cream to the surface, creating an extremely dense, smooth finish that can handle heavy traffic, forklifts, and industrial use for decades.